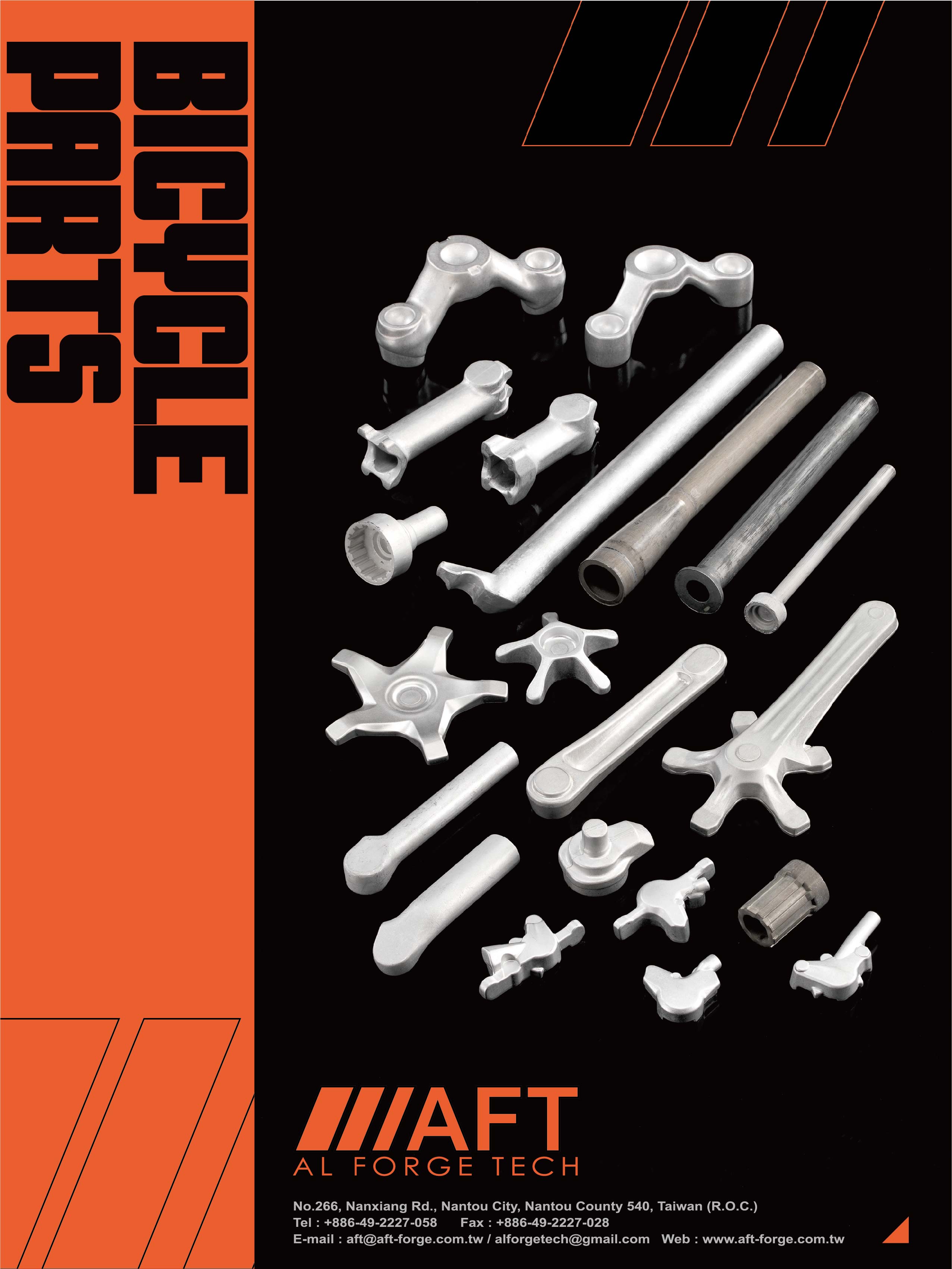

Aluminum Forging Bicycle Parts / Bike Parts

Forged Aluminum Components for Bikes Benefits

Aluminum forging is a common method used in the production of bike parts (including electric bikes). Common-seen forged aluminum bike parts include frames, handlebars, cranksets, and seat posts. The forging process also enhances the mechanical properties of the aluminum, making the parts stronger and more durable compared to other manufacturing methods like casting or machining. The following are benefits you can get from forged aluminum parts for bikes:

- Reducing the weight of the bike

- High strength-to-weight ratio

- Outstanding corrosion resistance and fatigue resistance

- Stronger and more durable compared to casting

- Improving performance and ride quality

Professional Solution for Forged Aluminum Parts of Bikes

As a distinguished forging factory with a wealth of industry expertise, Al Forge Tech has been a trusted partner in producing OEM aluminum forged bicycle components for a multitude of clients. Our production procedures adhere to rigorous quality management protocols, ensuring that each component attains the highest levels of customer satisfaction. Welcome to contact us for more details about forged aluminum components for electric bikes.