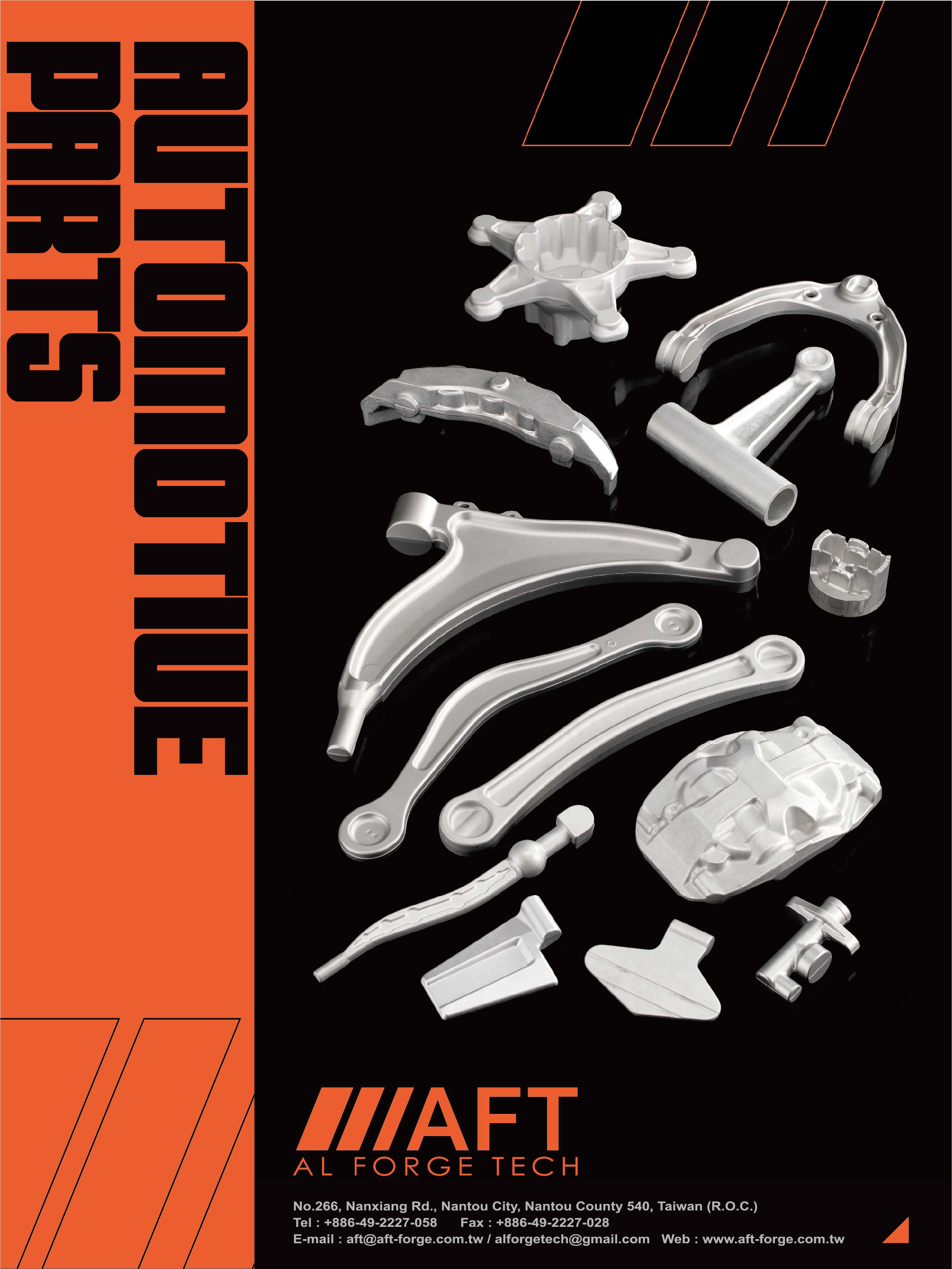

Aluminum Forging Automobile Parts

Benefits of Aluminum Automotive Forging Components

Aluminum forging is widely used in the automobile industry to produce various parts, including engine blocks, suspension components, wheels, and structural components. The high strength-to-weight ratio of aluminum makes it an ideal material for producing lightweight and durable automobile parts. By forging the aluminum, manufacturers can improve its mechanical properties, making it more resistant to stress and strain, and resulting in stronger and more durable aluminium forged automotive components. This results in improved fuel efficiency, performance, and durability of vehicles.

The use of aluminum forgings in automobile production can also help improve fuel efficiency and reduce emissions, as lighter weight vehicles require less energy to move. Additionally, aluminum forgings offer excellent resistance to corrosion, making them ideal for use in harsh automotive environments. Additionally, aluminum forging enables the production of complex shapes and geometries that cannot be achieved through other metal forming processes, making it ideal for producing high-performance automobile parts.

Al Forge Tech : Best Automotive Forging Companies

Al Forge Tech automotive forging supplier is able to offer custom service to help you make your own aluminum automotive forging components with our professional professing methods such as cold forging service and hot forging service, etc. If you have any questions about our services, welcome to contact Al Forge Tech, your reliable automotive forging manufacturers, at any time.